Learn how a major oil and gas producer has leveraged Teren’s environmental intelligence to become a leader in well pad reclamation.

The Challenge: Well Pad Reclamation is a Complex, Regulated Landscape

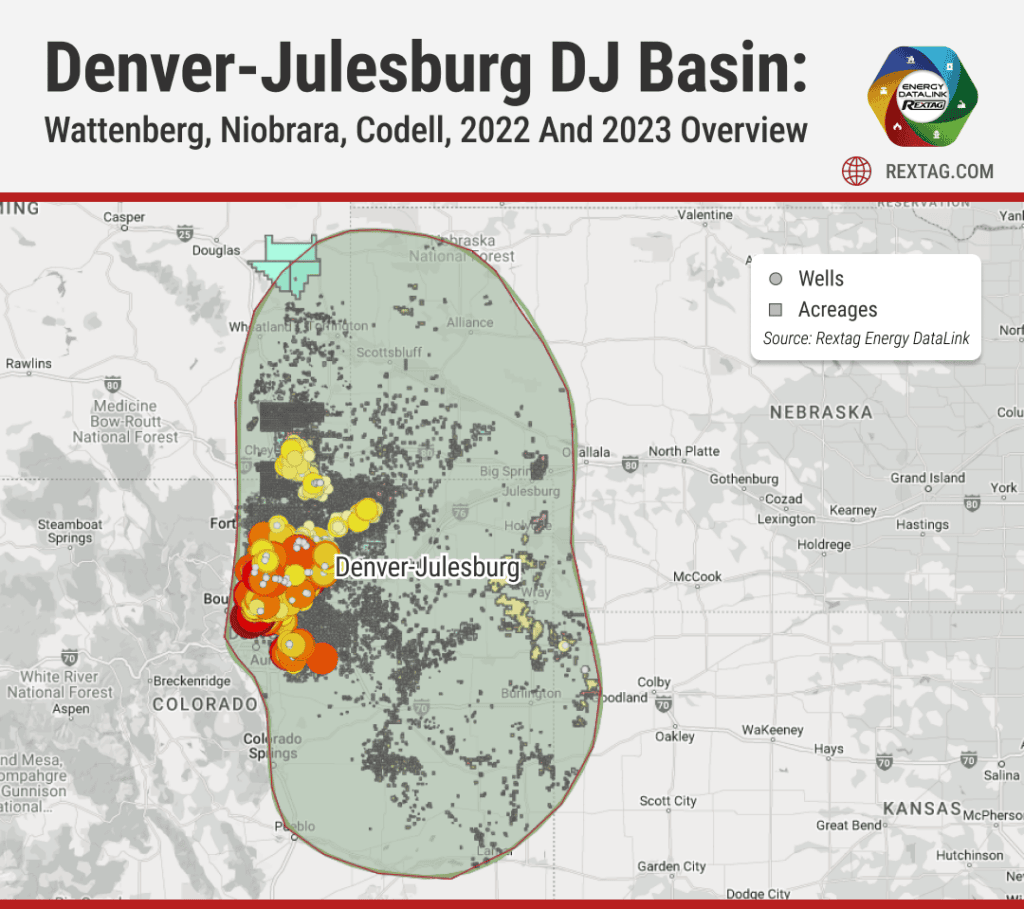

Well pad reclamation in Colorado’s Denver-Julesburg (DJ) Basin involves intricate processes and strict regulations. Companies acquire numerous assets over the years, and then often face difficulties in locating and classifying their well pads.

A major pain point is ensuring that these pads meet the Colorado Oil and Gas Conservation Commission’s (COGCC) requirement to revegetate the pad to at least 80% vegetative cover compared to the natural surrounding vegetation before being released from their permits. This process not only requires meticulous planning but also significant manpower and resources, which is has caused some producers to orphan their wells altogether.

Teren’s Innovative Approach

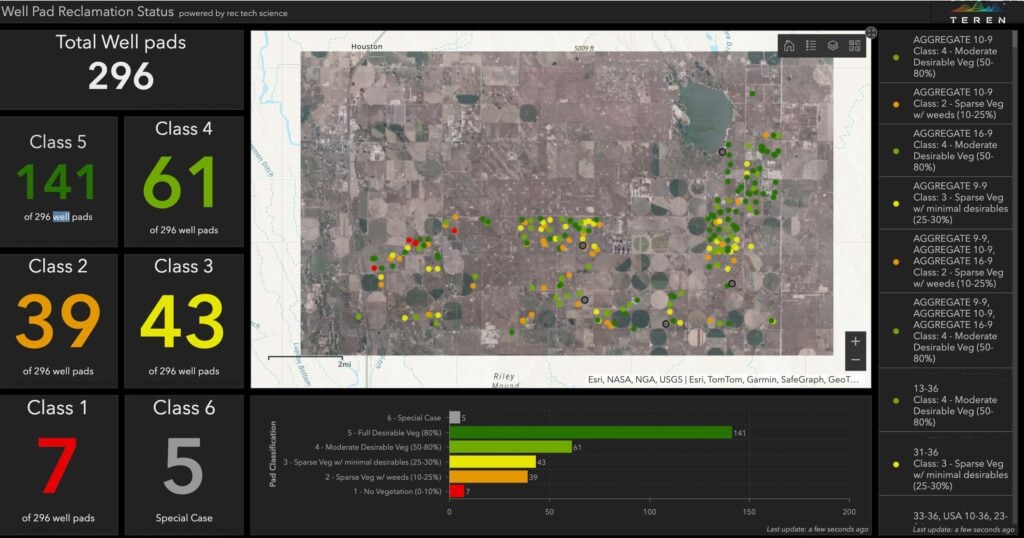

By integrating advanced LiDAR and imagery data with sophisticated models developed by the Teren team, Teren helped a major oil and gas producer classify and prioritize well pads for reclamation and permit release. These models consider various indices, including vegetation structure and vigor data, to provide a comprehensive analysis of each site.

Teren Data Engineer Elena Arroway, a key developer of the models, explains, “The data we collect through remote sensing allows us to classify the pads into different categories based on their vegetation levels. This helps companies know which pads can be released from permits and which ones need further reclamation work.”

The Result: Increased Efficiency, Safety, Accuracy and Environmental Stewardship

“By using remote sensing data, we can provide accurate assessments without the need for frequent site visits. This not only saves time and money, but also aligns with goals of modern upstream operators to minimize environmental impact”

Jacob Spurgin, Teren Solutions Engineer

This new approach provides a more accurate and objective assessment of well pad sites for operators, in addition to a reduction in on-site visits, which translates to lower labor costs, safety concerns, and a reduced carbon footprint.

Traditionally, companies must deploy personnel by vehicle to manually inspect individual well pads dispersed across a wide area, a process that was not only time-consuming and exposed staff to unnecessary safety risks, but also environmentally taxing due to vehicle emissions. In terms of inspection accuracy, human (ocular) assessment is subjective both from site to site and inspector to inspector, leading to inconsistencies in results. A qualitative, data-driven method is objective and more accurate than the human eye.

“By using remote sensing data, we can provide accurate assessments without the need for frequent site visits,” says Jacob Spurgin, a Teren Solutions Engineer. “This not only saves time and money but also aligns with goals of modern upstream operators of minimizing environmental impact.”

Moreover, the model developed by Teren allows for continuous monitoring and change detection over time. This means that companies can track the progress of their reclamation efforts and make data-driven decisions to optimize their resources.

A Timely Tool

With nearly 48,000 unplugged oil and gas wells in Colorado emitting on average 70 times more methane — a powerful greenhouse gas — than the U.S. average, Teren’s intelligence provides producers with a long-awaited solution to streamline and accelerate well pad reclamation.

To see Teren’s Well Pad Reclamation modeling in action, get in touch for a demo.

How can Teren help you?

We'd love to hear from you.

- Ready to dive deeper? -

Knowledge Hub

White Papers

Webinars