Introduction

Pipeline infrastructure serves as the backbone of global energy networks, delivering the resources that power industries and homes alike. Yet, these critical systems face unprecedented challenges from natural forces, which cause hundreds of pipeline incidents costing millions each year, according to the Pipeline and Hazardous Materials Safety Administration (PHMSA).

In this guide, we delve into the essential components of pipeline integrity management, exploring how advanced technologies and strategic approaches are safeguarding critical infrastructure against these escalating threats.

Understanding Pipeline Integrity Management

Pipeline integrity management (PIM) is a systematic and comprehensive approach to ensuring the safe, reliable, and efficient operation of pipeline systems. It encompasses a range of activities, processes, and technologies designed to maintain and improve the structural integrity and functionality of pipelines throughout their lifecycle.

Its primary goals include:

- Prevent Catastrophic Failures: Minimize the risk of leaks, ruptures, or other devastating events.

- Ensure Operational Safety: Protect communities, workers, and ecosystems.

- Minimize Environmental Risks: Reduce the impact of pipeline incidents on natural habitats.

- Optimize Asset Performance: Maximize the lifespan and efficiency of pipeline systems.

Key Components of Pipeline Integrity Management

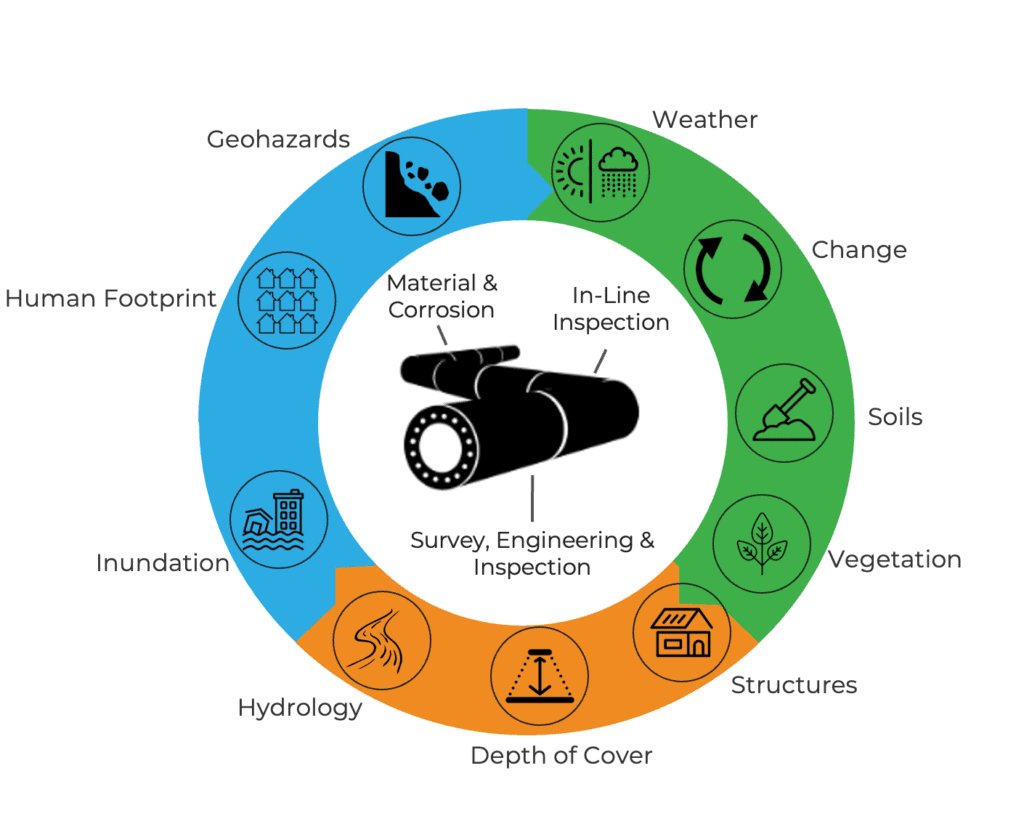

To achieve the objectives of pipeline integrity management, a variety of approaches are applied:

- Inspection and Monitoring:

- Regular Inspections: Using techniques such as inline inspection (ILI), hydrostatic testing, and visual inspections to detect and assess pipeline conditions.

- Real-time Monitoring: Implementing sensors and monitoring systems to track pipeline conditions and detect anomalies in real-time.

- Data Management and Analysis:

- As-Built Data: This include pipe material properties, construction records, and the location of the physical pipe.

- Engineering Critical Analysis (ECA) Data: providing analyses like corrosion growth rate assessment and strain-based assessment, ECA gives a comprehensive view of the pipeline’s fitness for service.

- Geospatial Data: Utilizing GIS and other mapping tools to manage and analyze spatial data related to pipeline locations and surrounding environments.

- Data Integration: Combining data from various sources (e.g., field inspections, in-situ monitoring, environmental conditions) to get a comprehensive view of the environment around the pipeline.

- Maintenance and Repair:

- Preventive Maintenance: Scheduling regular maintenance activities to prevent deterioration and address issues before they lead to failures.

- Timely Repairs: Conducting repairs promptly when issues are detected to restore pipeline integrity.

- Corrosion Control:

- Cathodic Protection: Applying electrochemical protection to prevent metal corrosion.

- Coatings and Linings: Using protective coatings and linings to shield pipelines from corrosive elements.

- Risk Assessment and Management:

- Hazard Identification: Identifying potential hazards that could compromise pipeline integrity.

- Risk Mitigation Plans: Developing and implementing plans to mitigate identified risks.

- Emergency Response Planning:

- Preparedness: Having plans and resources in place to respond quickly and effectively to pipeline emergencies.

- Training and Drills: Conducting regular training and emergency response drills for personnel.

Natural Force Threats:

Natural force threats to pipeline integrity management encompass various environmental and geophysical hazards that can affect the safety and functionality of pipelines. Here’s a summary of the key natural force threats:

- Geohazards:

- Earthquakes: Seismic activities can cause ground shaking, ground displacement, or fault movements, potentially rupturing or deforming pipelines.

- Landslides: Slope movements due to heavy rains or seismic events can displace pipelines, leading to strain or breakage.

- Subsidence: Gradual sinking or sudden collapse of ground can alter the support around pipelines, leading to stress and potential failure.

- Weather-related Threats:

- Flooding: Heavy rainfall and river overflows can erode pipeline foundations or bury pipelines under debris, affecting their operation and increasing corrosion risks.

- Temperature Extremes: High temperatures can lead to thermal expansion of pipelines, while extreme cold can make materials brittle and more susceptible to cracking.

- Windstorms and Hurricanes: High winds and flying debris can damage pipeline components, especially those that are above ground or in shallow burials.

- Hydrological Changes:

- River Scour and Channel Migration: Flowing water can erode soil around pipelines laid under riverbeds, exposing them to potential damage.

- Ice Jams: In colder regions, ice build-up and subsequent break-up can exert force on pipelines, risking structural integrity.

- Other Natural Events:

- Wildfires: Can directly damage pipelines through heat exposure and indirectly by destabilizing the soil structure, leading to erosion.

- Animal Activities: Burrowing animals or tree root growth can physically damage pipelines or their protective coatings.

Managing these threats typically involves risk assessment, regular monitoring, maintenance practices tailored to environmental conditions, and designing pipelines to withstand specific regional hazards. Coordination with environmental experts and adherence to regulatory standards are also crucial for effective integrity management.

An increased use of unmanned aerial systems (UAS) by many industries has allowed for the production of massive amounts of data. The quantity, however, is meaningless without the ability to transform big data collected from the field into actionable intelligence at the desktop. For pipeline operators, the transformation process requires efficient, scalable, and statistically robust analytic methods that complement and build upon traditional inspection and Integrity Management program protocols.

Conclusion

Pipeline integrity management is more critical than ever in 2024. By understanding natural force threats, leveraging advanced technologies, and maintaining a proactive approach, we can ensure the safety, reliability, and environmental responsibility of our critical infrastructure.

Discover how Teren elevates pipeline integrity management.

How can Teren help you?

We'd love to hear from you.

- Ready to dive deeper? -

Knowledge Hub

White Papers

Webinars